e6.20 e6.10 AUTOMATIC LENS EDGERS

Grinds all current lens materials including Polycarbonate accurately and quickly.

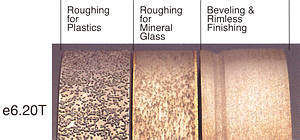

Yet, the Model e6.20T cuts out both plastic and mineral glass lenses at high specializing in each material.

A built-in controlled beveling unit allows you to fine-tune the bevel placement on hight-power lenses.

Three-degrees head pressures can be selected according to the style of lens.

An anti-foam coolant system (water tank & pump) is standard.

A direct water supply system (city water connection kit) and motorized lens chucking system also available from the optional accessories.

The model e6.20 series includes a lens measuring system that enables you to verify the finished lens size without removing the lens from the machine.

| There's one to fit your needs! | ||

|

Model e6.20T

Lens measuring system Installed

|

|

|

|

Model e6.20V

Lens measuring system Installed

|

|

|

|

Model e6.20S

Lens measuring system Installed

|

|

|

|

Model e6.20P

Lens measuring system Installed

|

|

|

|

Model e6.10T

Lens measuring system Not Installed

|

|

|

|

Model e6.10S

Lens measuring system Not installed

|

|

|

|

Model e6.10P

Lens measuring system Not installed

|

|

|

|

Wheel specs

A:Electroplated roughing(18mm wide) | ||

| meter of Lens Acceptable | Min:22mm in height(Rimless) / 24mm in height(beveling) with small lens chucks Max:100mm(Φ) |

|---|---|

| Dimensions | 430(W)x430(D)x350(H)mm 650(H)mm when cover is open |

| Weight | 33kg(Main unit) / 5kg(Accessories) |

| Power Requirements | 100-120V/60Hz AC or 200-240V/50Hz AC, 250W |